Case Studies

Sydney Cricket Ground (Sydney NSW)

Unison Joint's DzFT/Aquo P®

In 2013 SCG Stage 2 was constructed. It was imperative that The Noble and Bradman Stands were water sealed. Unisons Managing Director, Bernie Scott met with AW Edwards Construction representatives. After looking at the design on site and listening to the clients concerns, Bernie suggested the specially formulated polyethylene seal with the DzFt flextread topper(PB/AR). Hence, no leaks, no damage to seal with high heels, no trip hazard! The Unison’s DzFT/Aquo P® was installed together with other cover plate systems throughout the facility. Aquo P® proved it is an ideal choice for use in seating plats. See reference below.

Suncorp Stadium (Brisbane QLD)

Unison Joints stopped the leaks

In 2003 the transformation of Lang Park to Suncorp Stadium was completed. Owned by Stadiums Queensland, Suncorp is a colosseum type stadium with steep seating tiers, which provide excellent views of the ground from virtually anywhere in the stands. As is common to other stadiums, there are major movement-gaps which divide the structural concrete frame, from top to bottom, at four designed positions around the building. In such a large structure, these gaps have considerable movement. There had been considerable leaking within the failing joints initially installed. By 2016 these gaps were often the cause of water inundation. Duratec Queensland were contracted to replace the seals and cover plates to ensure no water ingress, or trip/slip hazard.

Unison Joint's Aquo P®

Between September 2017, and April 2020 the major movement joints at Suncorp Stadium had the waterproof seals replaced. Unison’s Trademarked Aquo P® was employed to provide a watertight seal. The project included sealing joints in horizontal concourses, and precast seating plats. Movement gap sizes varied extensively: site measurements are taken, and Aquo P® is cut-to-size, manufactured 30% bigger than the gap in our Brisbane factory. The Aquo P®’s ease of reshaping and weld-ability make it a fantastic 100% watertight, high-movement building and seismic movement-joint seal. During the expansion joint refurbishment project, it was imperative to minimise time spent, with gaps open to weather conditions. Fast manufacture time at Unison alleviated concerns. The client has advised he is happy with the outcome (no leaks).

Ministry of Education Building, Riyadh (Saudi Arabia)

Building Rehabilitation

Ministry Of Education Building, Riyadh, Saudi Arabia

In 2012 Unison Joints was contacted by Bullivant Arabia to potentially supply structural bearing pads. This was for remedial works on a resurrected large government-owned building construction project in Riyadh.

Bullivant Arabia Ltd is a Saudi British JV specialising in structural appraisal, design, and execution of: structural grouting, underpinning, structural rehabilitation, concrete repair, shot-creting, and various other foundation repair and design works.

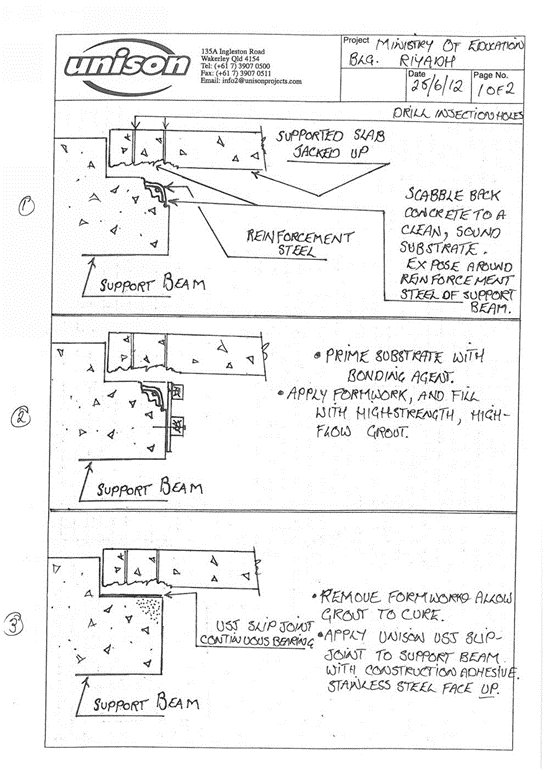

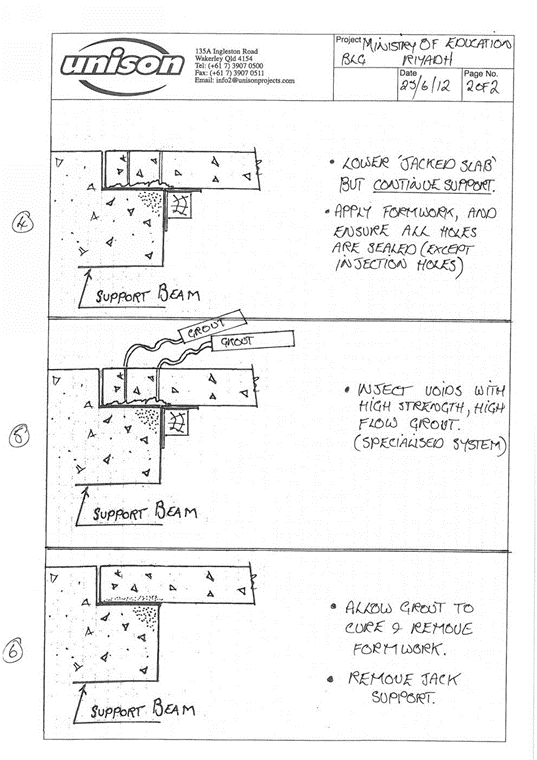

Unison’s AccS Slip Joints (continuous bearing pads) were quoted by Mr Bernie Scott. The client had some doubts as to how these could be employed. Mr Scott drafted a series of sketches which outlined the required procedures for rehabilitation of corbel joints at the site

Unison's Slip Joints

The proposal was approved by the client and a subsequent order placed by the specialist contractor, Bullivant.

500.5 metres of AccS70/30/180 Slip Joint was assembled in Unison Joints Pty Ltd factory in Tingalpa and shipped to Riyadh.

Mr Scott was required to visit the site for inspection. Bullivant Arabia Ltd delivered excellent work to rehabilitate this once damaged structure, while Mr Scott experienced the pleasures of the local cuisine.